Release time:2023-11-12 15:30:13 Hits: Current position: Home > News

This article mainly introduces:

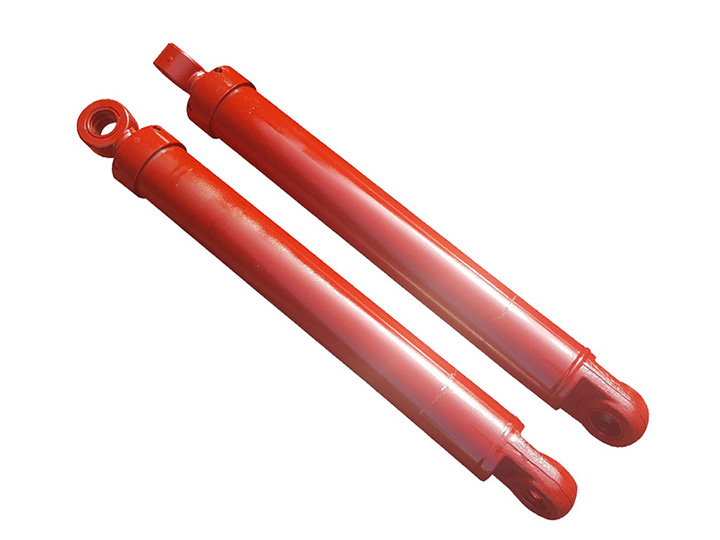

Australia hydraulic cylinder,constant speed cylinder manufacturer,constant speed cylinder

(Australia constant speed cylinder,produced by Hengyu Hydraulic Co., Ltd)

constant speed cylinder are widely used in Australia,because of no need for deceleration device,long service life,smooth movement.So our company has designed constant speed cylinder for customers from Australia.

The commonly used buffer structure of the constant speed cylinder is composed of a piston boss and a constant speed cylinder head groove. When the piston moves close to the constant speed cylinder head, it gradually enters the groove, and the oil in the groove is extruded through the gap between the boss and the groove, which increases the oil return resistance, produces the braking effect and realizes the buffer. Generally, a buffer mechanism should be used when the pressure is above 10MP.

The piston rod of the constant speed cylinder has two kinds of solid rod and hollow rod, and one end of the hollow piston rod needs to be set aside for welding and heat treatment. The solid piston rod material is 35, 45 steel, and the hollow piston rod material is 35, 45 seamless steel pipe. After rough machining, the piston rod is conditioned to 229~285HB in India, and if necessary, the hardness is 45~55HRC after high-frequency quenching.

When the constant speed cylinder is installed, the piston and the constant speed cylinder head and other parts have large mass, large size and large inertia, even if there is a lifting equipment auxiliary installation, because the specified clearance is small, no matter how hard it will be put into, therefore, the end of the piston or the constant speed cylinder head boss is easy to cause scars when it hits the inner surface of the constant speed cylinder wall. The solution to this problem: for a large number of small products, the use of autocratic assembly oriented tools during installation; For heavy, thick and large large and medium-sized constant speed cylinders, only careful and careful operation can be avoided.

When the constant speed cylinder is in use, once the seal and guide support ring are found to be defective, the seal with the same structural form and appropriate material should be replaced according to the structural form of the constant speed cylinder seal to be repaired, so as to minimize the thickness of the oil film between the seal and the sealing surface and reduce the leakage of the seal.

What is a variable amplitude cylinder?

The type of variable amplitude cylinder is: double acting piston type cylinder, single acting plunger type cylinder, double acting two-stage telescopic cylinder. Double acting piston cylinder is the most common application. The oil cylinder has two oil outlets, and when the oil is fed into the A port, the oil is returned to the B port; If the oil inlet of the B port is returned to the oil of the A port, the reciprocating movement of the piston depends on the effect of pressure. Single-acting plunger (or piston) cylinder has only one oil port, the pressure oil can only supply oil to one side of the plunger in the cylinder, the plunger moves in one direction under the action of pressure oil, and the return stroke of the plunger is driven by the gravity of the lifting arm, such as the LT1040 truck crane variable amplitude cylinder. The double-acting two-stage telescopic cylinder is a set structure, and the two-stage piston rod is like a tie rod antenna set in the cylinder barrel.

How to disassemble the big nut that excavate the oil cylinder piston of the excavator?

If you want to be safe, look for a special unloading place for this thing, which is an oil cylinder on top of a turntable with a large nut attached to the center of the turntable. If you're in the field just pin the head of the cylinder to one end, use a big homemade wrench to hold the nut in place, and then get a digging machine and push it down, and it opens.