Release time:2023-11-12 15:31:20 Hits: Current position: Home > News

This article mainly introduces:

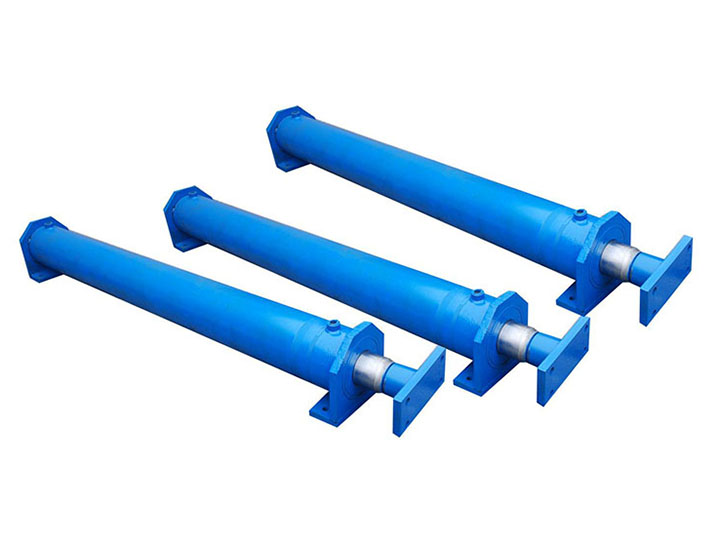

Azerbaijan hydraulic cylinder,push and pull the cylinder manufacturer,push and pull the cylinder

(Azerbaijan push and pull the cylinder,produced by Hengyu Hydraulic Cylinder Factory)

push and pull the cylinder are widely used in Azerbaijan,because of no need for deceleration device,long service life,smooth movement.So our company has designed push and pull the cylinder for customers from Azerbaijan.

The meaning of the push and pull the cylinder model marked by the push and pull the cylinder manufacturer: for example, 160/100-1150, its meaning: from a professional point of view, 160 refers to the push and pull the cylinder diameter, which is 160mm, and the 100 behind refers to the rod diameter, which is 100mm. The 1150 refers to the push and pull the cylinder stroke, which is 1150mm. Therefore, on this point, we should have a correct understanding and can not make mistakes.

When the push and pull the cylinder is repaired, its inner and outer diameter and roundness should be accurately measured. If the inner hole of the push and pull the cylinder is badly worn, it can be repaired by grinding the mandrel or honing on the boring machine. If the piston is worn, it can be repaired by electroplating, and serious wear should be replaced.

When the push and pull the cylinder is customized, if there are high requirements for the quality of the push and pull the cylinder, it is best to use rolling processing, because the surface layer has surface residual compressive stress, which helps to close the surface of the small crack, preventing the expansion of erosion. Thus, the corrosion resistance of the surface can be improved, and the fatigue crack can be delayed or expanded, and the fatigue strength of the push and pull the cylinder can be improved. By rolling forming, a cold working hardening layer is formed on the rolling surface, which reduces the elastic and plastic deformation of the contact surface of the grinding pair, thereby improving the wear resistance of the inner wall of the push and pull the cylinder and avoiding the burn caused by grinding. After rolling, the reduction of surface roughness value can improve the matching property.

push and pull the cylinder body inspection: The inner surface of the push and pull the cylinder and the piston seal are the main factors causing the leakage in the push and pull the cylinder, if the push and pull the cylinder has a longitudinal tensile mark, even if the new piston seal is replaced, it can not effectively eliminate the fault, the inner surface of the push and pull the cylinder mainly checks whether the dimensional tolerance and shape and position tolerance meet the technical requirements, there is no longitudinal tensile mark, and measures the depth of the longitudinal tensile mark, in order to take the corresponding solution.

What does the maximum output force of the cylinder piston mean?

The maximum output of the cylinder is related to the pressure of the hydraulic system that you link to the cylinder. For example, the rated maximum output thrust of the MOB 50 cylinder is 1.3 tons and the rated pressure is 7Mpa. That is, when the input hydraulic oil pressure of the cylinder reaches 7Mpa, the maximum output thrust of the cylinder is only 0.98 tons. When the input hydraulic pressure is only 5Mpa, the maximum output thrust of the cylinder is 1.3 tons. Because the pressure of the cylinder limit is only 7Mpa, if the oil pressure of the input system exceeds 7Mpa, the cylinder can not withstand the pressure burst, and it is damaged.

What adhesive should be used when the cylinder is cracked?

There is a kind of cast iron glue, industrial products market can buy, A, B formula, that is, a tube is A, a tube is B, when used proportionally prepared, check the instructions. Polish the glue after it dries, and then grind it again.