Release time:2023-11-12 15:31:53 Hits: Current position: Home > News

This article mainly introduces:

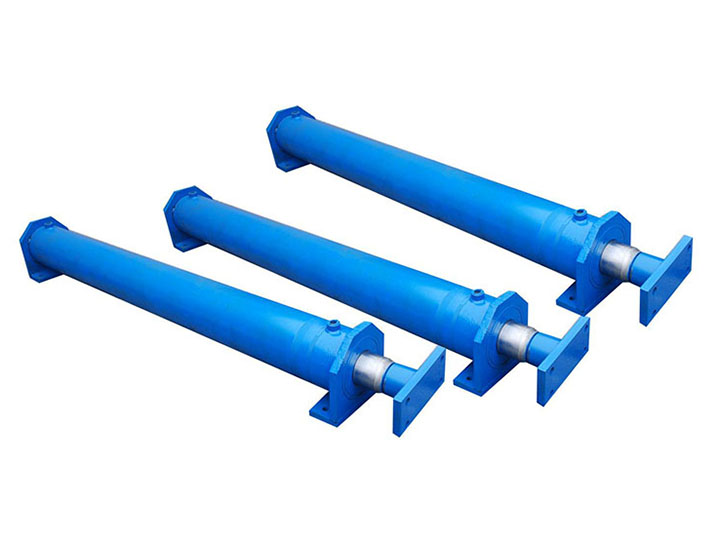

India hydraulic cylinder,push and pull the cylinder manufacturer,push and pull the cylinder

(India push and pull the cylinder,produced by Hengyu Group)

push and pull the cylinder are widely used in India,because of excellent temperature resistance,no transmission clearance,powerful torque.So our company has designed push and pull the cylinder for customers from India.

push and pull the cylinder is the most important part of construction machinery, the traditional processing method is: broaching push and pull the cylinder block - fine boring push and pull the cylinder block - grinding push and pull the cylinder block. The rolling method is: broaching push and pull the cylinder block - fine boring push and pull the cylinder block - rolling push and pull the cylinder block, the process is 3 parts, but the time is compared: grinding 1 meter of the push and pull the cylinder block is about 1-2 days, rolling 1 meter of the push and pull the cylinder block is about 10-30 minutes. Input comparison: grinding machine or quilting machine (tens of thousands - millions), rolling knife (ten thousand - tens of thousands). After rolling, the surface roughness of the hole decreases from RA3.2-6.3 μm before rolling to Ra0.4 ~ 0.8μm, the surface hardness of the hole increases by about 30%, and the fatigue strength of the inner surface of the push and pull the cylinder increases by 25%. If the push and pull the cylinder life is only considered, it is increased by 2 to 3 times, and the boring and rolling process is 3 times more efficient than the grinding process In particular, if you want to make high-quality push and pull the cylinders, you must take the rolling production process. After the push and pull the cylinder is rolled, there is no sharp tiny edge on the surface, and long-term motion friction will not damage the seal ring or seal, which is particularly important in the hydraulic industry.

The push and pull the cylinder should be used as far as possible to avoid the transverse force, sometimes the piston rod to bear the transverse load is too large, especially do not force or pull the push and pull the cylinder, bite. Elimination method: When installing the push and pull the cylinder, ensure that the axis position of the push and pull the cylinder is consistent with the direction of movement; Make the load borne by the push and pull the cylinder as far as possible through the push and pull the cylinder axis, to avoid the phenomenon of eccentricity.

The difference between the plunger push and pull the cylinder and the piston push and pull the cylinder is that the piston in the push and pull the cylinder is replaced by a shaft plunger, which is used in hydraulic transmission requiring a long mechanical stroke, and can only input pressure oil from one direction, pressurize in a single direction, and form a thrust to push the plunger to move. The return trip of the plunger depends on the plunger itself to fall, and some rely on the spring to push back to the original position. Usually used plunger type push and pull the cylinder, its inner hole does not need mechanical finishing, as long as the plunger round grinding can be assembled.

The pressure, temperature, medium and speed of different types of seals are not the same, water-ethylene glycol medium (HFC) can not be sealed with polyurethane, it can only use rubber seal; When the push and pull the cylinder is running fast, it must be sealed with slip ring, such as Sterseal, Glairing, GD1000K, TDI, etc., when the running speed is slow, Yx, U, V combination seals can be used; Fluorine rubber seal is used in high temperature and high pressure environment; When the running speed is fast, the buffer sleeve and buffer valve must be considered.

How big is a 300-ton cylinder piston?

The rated pressure of the oil pump is 31.5 mpa, the nominal pressure of the hydraulic press is 3150 kN, then the calculated cross-sectional area of the cylinder: S=3150000/31500000=0.1 square meters diameter is: 2* root sign (0.1/3.14) =2*0.178 m =0.356 m 3150 kN hydraulic press is commonly equipped with 31.5 mpa 63 l/min axial piston pump. There are many variable forms of axial piston pump, and the motor size of the pump with the same flow and pressure is not uniform. 31.5 mpa 63 L/min automatic variable pump, can be equipped with 15 kW 4 stage motor; The manual variable pump needs to be equipped with 22 kW 4-stage motor.

How to deal with the surface degreasing process before spraying paint after cylinder assembly, and what degreasing agent is used?

Cylinder painting, generally using the following process (note: the cylinder is best painted, do not spray powder coating, because the powder coating curing temperature is high, will lead to sealing defects and oil leakage) : Pre-degreasing - degreasing - washing - washing - pickling - washing - washing - table adjustment - phosphating - washing - washing - drying - polishing - spray primer - spray paint degreasing agent generally use neutral or weak alkaline degreasing agent, phosphating liquid generally use zinc phosphating liquid.