Release time:2023-11-12 15:33:34 Hits: Current position: Home > News

This article mainly introduces:

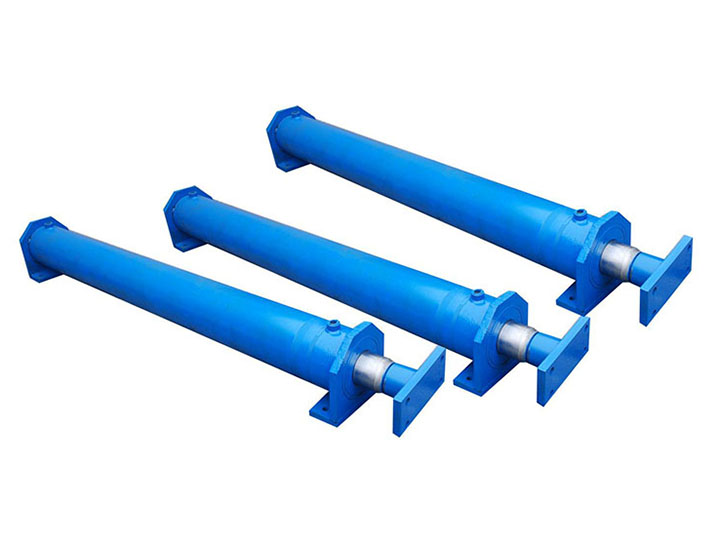

Hungary hydraulic cylinder,push and pull the cylinder manufacturer,push and pull the cylinder

(Hungary push and pull the cylinder,produced by Hebei Hengyu company)

push and pull the cylinder are widely used in Hungary,because of no transmission clearance,powerful torque,clever hydraulic energy conversion.So our company has designed push and pull the cylinder for customers from Hungary.

push and pull the cylinder and hydraulic station selection: Select the type and structure of the push and pull the cylinder according to the operation requirements of the main engine. According to the external load force borne by the push and pull the cylinder, such as gravity, friction force of the external mechanism, inertia force and working load, determine the load change law of the push and pull the cylinder in each stage of the stroke and the power value that must be provided. Determine the diameter of the piston and piston rod according to the working load of the push and pull the cylinder and the selected oil working pressure. the flow rate of the hydraulic pump is determined according to the movement speed of the push and pull the cylinder, the diameter of the piston and the piston rod.

If the seal of the push and pull the cylinder is abnormal wear, you can check whether the speed control valve is improperly adjusted, resulting in too high back pressure and improper installation of the seal or hydraulic oil contamination. The second is whether there is a foreign body entering the assembly and the quality of the sealing material is not good. The result is that the action is slow and weak, and in serious cases, it will cause damage to the piston and push and pull the cylinder, and the phenomenon of "pulling the push and pull the cylinder" appears. The treatment method is to adjust the speed control valve, and the necessary operation and improvement should be done according to the installation instructions.

The cavitation of the push and pull the cylinder has a great influence, and to avoid it, it is necessary to use the hydraulic oil reasonably and ensure the quality of the hydraulic oil. If the anti-foam property of the oil is poor, it is easy to produce foam, resulting in cavitation. Secondly, the change frequency of oil pressure is too fast and too high, which will also directly cause the formation of bubbles and accelerate the rupture rate of bubbles. The test shows that the speed of cavitation will be accelerated in the part with high frequency of pressure change. For example, at the inlet and outlet of the push and pull the cylinder, due to the relatively high frequency of pressure changes, the degree of cavitation is also relatively higher than that of other parts. In addition, overheating of the oil will also increase the probability of cavitation.

push and pull the cylinder body inspection: The inner surface of the push and pull the cylinder and the piston seal are the main factors causing the leakage in the push and pull the cylinder, if the push and pull the cylinder has a longitudinal tensile mark, even if the new piston seal is replaced, it can not effectively eliminate the fault, the inner surface of the push and pull the cylinder mainly checks whether the dimensional tolerance and shape and position tolerance meet the technical requirements, there is no longitudinal tensile mark, and measures the depth of the longitudinal tensile mark, in order to take the corresponding solution.

Why can't the hydraulic cylinder be replaced with water?

Hydraulic oil for hydraulic transmission has a variety of requirements for viscosity, density, flow rate, and temperature, which are not available for water.

What material should be selected to seal the cylinder?

The choice of material for sealing is related to the working environment, strength, and medium of your equipment.