Release time:2023-11-15 10:42:13 Hits: Current position: Home > News

This article mainly introduces:

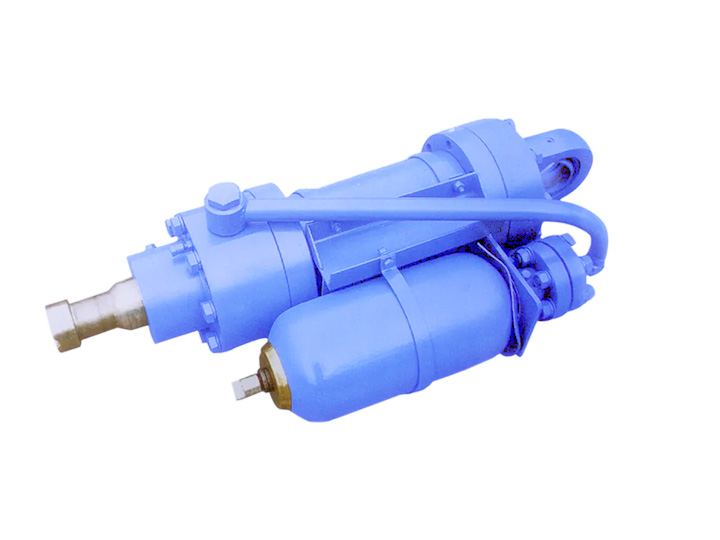

Spain hydraulic cylinder,accumulator hydraulic cylinder manufacturer,accumulator hydraulic cylinder

(Spain accumulator hydraulic cylinder,produced by Hebei Hengyu company)

accumulator hydraulic cylinder are widely used in Spain,because of powerful torque,clever hydraulic energy conversion,simple structure and reliable operation.So our company has designed accumulator hydraulic cylinder for customers from Spain.

The accumulator hydraulic cylinder should not be mixed with foreign objects during assembly, which will cause scars. Before the total assembly of the accumulator hydraulic cylinder, all parts must be fully removed and cleaned. When the parts are installed with burrs or dirt, foreign objects are easily embedded into the surface of the accumulator hydraulic cylinder wall due to the stiffness and the weight of the parts, causing scars.

Do not enter foreign bodies when installing the accumulator hydraulic cylinder block. The place where the installation operation is carried out, the conditions are not good, and foreign bodies can be entered unconsciously. Therefore, the installation site must be cleaned up around, especially the place where the parts are placed must be cleaned, so that there is no dirt.

accumulator hydraulic cylinder abnormal sound, hysteresis phenomenon cause and elimination method: the piston rod is extended with abnormal sound and hysteresis, if the accumulator hydraulic cylinder is placed for a period of time, the accumulator hydraulic cylinder may enter the air, and the movement can be normal after dozens of repeated movements. If it still cannot be eliminated, check whether the load is aligned with the axis of the piston rod; Retracted piston rod installation helps to align the load with the piston rod. If the flow is unstable, it will also lead to abnormal movement of the piston rod. Check the relevant components of the hydraulic system.

When the accumulator hydraulic cylinder thrust is insufficient, check the hydraulic circuit for leaks. Including leakage of valves and hydraulic lines. The inspection method is to check and eliminate the leakage of the hydraulic connection line by manipulating the reversing valve. Also consider the relief valve. If the relief valve enters the dirt and jams the spool, so that the relief valve is normally open, the hydraulic oil will flow directly back to the tank through the relief valve bypass, resulting in no oil in the accumulator hydraulic cylinder. If the load is too large, although the regulating pressure of the relief valve has reached the maximum rating, the accumulator hydraulic cylinder still cannot get the thrust required for continuous action without action. If the regulating pressure is low, the pressure is insufficient to achieve the required vertebra force, which is manifested as insufficient thrust. Check and adjust the relief valve at this time.

What is the thin cylinder used for?

The principle is no different from ordinary cylinders, that is, the installation space is small, the formation is small, and it is suitable for some special occasions. For example, the space is compact and the place of small travel is used.

How is the hydraulic cylinder tempered?

The purpose of the tempering treatment is to make the piston rod have comprehensive mechanical properties of strength, hardness, plasticity and toughness, and the internal structure is uniform and fine tempered sorbite, so as to prepare the organization for subsequent surface quenching. The length of the long cylinder piston rod is 3800-4200, and the diameter is Φ90-Φ110mm, so its heating equipment uses a 150KW well resistance furnace or 600KW suspension continuous resistance heating furnace, and the temperature is controlled by two areas. Heat treatment process parameters: in the shaft furnace, a furnace is suspended with 4 pieces, the quenching heating temperature is 830±10℃, and after holding heat for 160min, it is divided into two times for quenching, and two pieces are quenched each time, and the circulating cooling water is used for cooling.