Release time:2023-11-18 17:15:20 Hits: Current position: Home > News

This article mainly introduces:

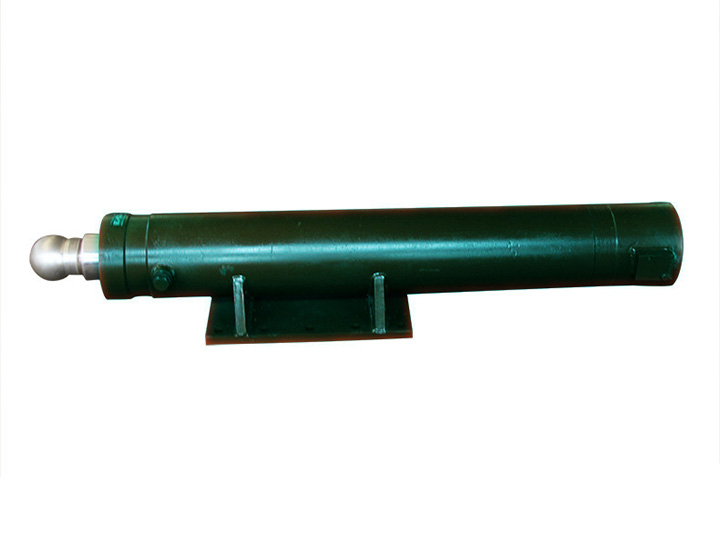

Turkey hydraulic cylinder,supporting cylinder manufacturer,supporting cylinder

(Turkey supporting cylinder,produced by Hengyu Hydraulic Co., Ltd)

supporting cylinder are widely used in Turkey,because of high work efficiency,excellent fatigue and impact resistance,no need for deceleration device.So our company has designed supporting cylinder for customers from Turkey.

The piston rod of the supporting cylinder has two kinds of solid rod and hollow rod, and one end of the hollow piston rod needs to be set aside for welding and heat treatment. The solid piston rod material is 35, 45 steel, and the hollow piston rod material is 35, 45 seamless steel pipe. After rough machining, the piston rod is conditioned to 229~285HB in India, and if necessary, the hardness is 45~55HRC after high-frequency quenching.

The supporting cylinder should be avoided for a long time without use, if it is indeed idle for a long time for some reason, it should also be regularly turned on for empty operation, so that its parts can be fully lubricated, so as to avoid rust on the working surface and affect the normal work in the future. (If it cannot be turned on and run, a small amount of lubricating oil can be applied on its outer surface for protection) ' The use of the supporting cylinder should pay attention to: the operation should be as far away from the supporting cylinder as possible, to avoid falling objects, knocking, rubbing the supporting cylinder coating. When cleaning the supporting cylinder, only use soft materials (such as cotton) to wipe, and do not scratch high-hardness materials. Do not use the supporting cylinder when the oil temperature exceeds 70 ° C.

In the case of serious wear on the inner surface of the supporting cylinder, or when there is a deep longitudinal tensile mark, it should be mapped according to the physical object and re-produced by the professional manufacturer according to the supporting cylinder manufacturing process for replacement. The supporting cylinder can also be repaired with TS311 antiwear repair agent. TS311 anti-wear repair agent is mainly used for the repair of worn and slipped metal parts.

The repair method of the supporting cylinder: the repair of the supporting cylinder must use brush plating. This is because this repair method can be carried out on site, and the repair effect is good. In this way, loading and transportation can be eliminated to shorten the repair time and improve work efficiency. In addition, the coating obtained by brush plating has good binding force and will not have obvious boundaries. Moreover, the repair surface has high hardness and good wear resistance.

What steel pipe does hydraulic cylinder use? This problem is very general. Carbon steel pipe or ordinary seamless steel pipe are all ok, but then there are rolling, quilting, heat treatment and other steps, and the requirements are different, the wall thickness is different, the material is different. It depends on the circumstances.

How is the hydraulic cylinder selected in the mechanical design manual?

First of all, it is necessary to meet your work needs, and the second is to meet the structural space of the cylinder and accessories. Three to consider the other parameters of the cylinder.