Release time:2023-11-18 17:15:34 Hits: Current position: Home > News

This article mainly introduces:

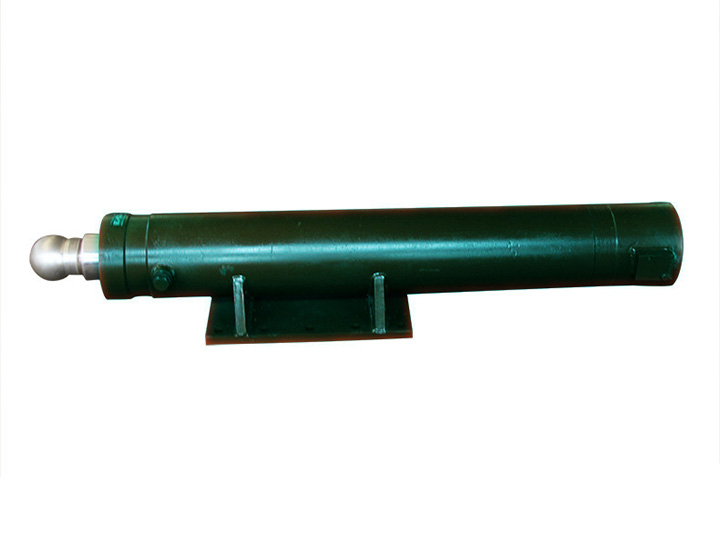

Guatemala hydraulic cylinder,supporting cylinder manufacturer,supporting cylinder

(Guatemala supporting cylinder,produced by Hengyu Hydraulic Cylinder Factory)

supporting cylinder are widely used in Guatemala,because of smooth movement,high work efficiency,excellent fatigue and impact resistance.So our company has designed supporting cylinder for customers from Guatemala.

In the case of serious wear on the inner surface of the supporting cylinder, or when there is a deep longitudinal tensile mark, it should be mapped according to the physical object and re-produced by the professional manufacturer according to the supporting cylinder manufacturing process for replacement. The supporting cylinder can also be repaired with TS311 antiwear repair agent. TS311 anti-wear repair agent is mainly used for the repair of worn and slipped metal parts.

The repair method of supporting cylinder wear: 1. Metal repair material is applied to the scratched surface; The first layer should be thin, uniform and fully covered with the scratched surface to ensure the best adhesion between the material and the metal surface, and then apply the material to the entire repair site and press repeatedly to ensure that the material is filled and reaches the required thickness, so that it is slightly higher than the surface of the guide rail; 2, the material at 24℃ to fully achieve the performance of 24 hours, in order to save time, can be through the tungsten halogen lamp to increase the temperature, the temperature rises 11℃, the curing time will be reduced by half, the best curing temperature 70℃; 3. After the material is cured, use a fine grinding stone or a scraper to repair and smooth the material higher than the surface of the guide rail, and the construction is completed.

Most of the failure of the supporting cylinder is because there is a foreign body in the supporting cylinder into the failure of the supporting cylinder, the most problematic is that it is difficult to determine when the foreign body is into the supporting cylinder. After a foreign body enters, if the outer side of the sliding surface of the piston is equipped with a seal with a lip edge, then the lip edge of the seal can scrape the foreign body when working, which is beneficial to avoid scratching. However, the piston equipped with 0-shaped sealing ring has a sliding surface at both ends, and foreign bodies are sandwiched between this sliding surface, which is easy to form scars.

The definition of the minimum starting pressure of the supporting cylinder refers to the minimum working pressure of the supporting cylinder in the no-load state, which is a comprehensive index reflecting the manufacturing and assembly accuracy of the supporting cylinder parts and the size of the sealing friction.

Hydraulic cylinder application areas?

1, in the machine tool industry, 85% of the machine tool transmission system adopts hydraulic transmission and control. Such as grinding machine, milling machine, planer, broaching machine, press, shearing machine, and combined machine tools. 2, in the metallurgical industry, electric furnace control system, rolling mill control system, open furnace charging, converter control, blast furnace control, strip deviation and constant tension device are all using hydraulic cylinders. 3, in the construction machinery, the general use of hydraulic transmission, such as excavators, tire loaders, truck cranes, crawler bulldozers, tire cranes, self-propelled scrapers, graders and vibration rollers. 4, in agricultural machinery, the use of hydraulic cylinders is also widely used, such as combine harvesters, tractors and so on.

Is the hydraulic cylinder leaking because there is no pressure?

HC hydraulic cylinder common leakage reasons, first: most of the reasons are because the seal surface wear or aging leads to poor sealing, so there is no pressure to operate, as long as the piston seal can be replaced. Second: It may also be the piston rod strain, repair the piston rod is good. If it is because the piston strength is not enough and the playing time is long, it is necessary to replace the piston.