Release time:2023-12-05 14:27:13 Hits: Current position: Home > News

This article mainly introduces:

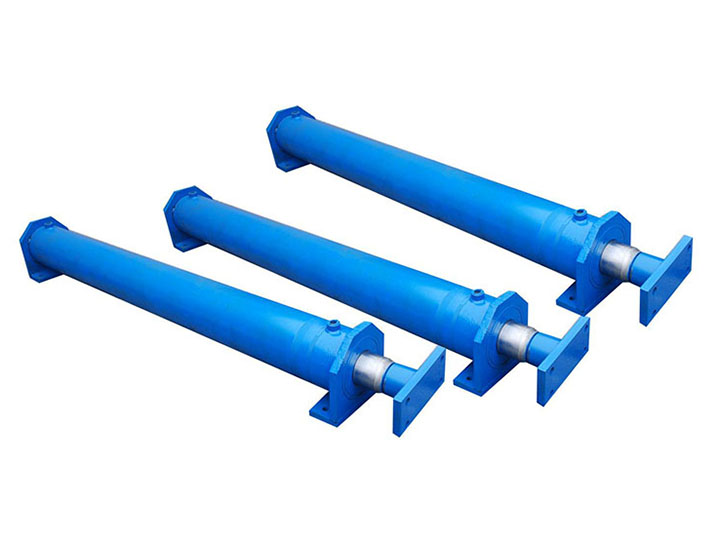

El Salvador hydraulic cylinder,push and pull the cylinder manufacturer,push and pull the cylinder

(El Salvador push and pull the cylinder,produced by Hebei Hengyu company)

push and pull the cylinder are widely used in El Salvador,because of no transmission clearance,powerful torque,clever hydraulic energy conversion.So our company has designed push and pull the cylinder for customers from El Salvador.

We can not just consider the price and ignore the quality when we purchase the push and pull the cylinders. Now some manufacturers produce unqualified products in order to reduce costs, the piston rod is not adjusted, the rod coating is not enough, the push and pull the cylinder finish can not reach, the guide sleeve should use copper, but instead of ductile iron, although the cost is reduced, the quality of the push and pull the cylinder is not required.

push and pull the cylinder piston rod material introduction: In general, we use 45 steel to produce push and pull the cylinder piston rod. It has a large impact force when it is used, and some good performance steel are also used in the heavy load transmission. In order to have enough work intensity when using, and can ensure normal use, this is still more critical to have a detailed understanding of the material.

The role of the push and pull the cylinder in the mold industry: the push and pull the cylinder has a variety of uses in the mold, one is that the core distance is very large, or because of the mechanism of the product, only the push and pull the cylinder is reasonable or more cost saving. Let the side core be extracted before opening the mold. Hot runner is mainly based on the product to decide, sometimes customers require the use of hot runner, the price is more expensive, but there are many benefits, you can save raw materials, shorten the molding cycle The push and pull the cylinder has an irreplaceable role in the heavy industry production process: it is mainly used in places that need to support heavy objects for a long time, and it can still support heavy objects when the oil pressure is removed, and it is safe and reliable. Can be used underwater, single action, load reversion, nut self-locking to make the load safer, especially in large projects, is easy to operate control and self-locking jack, designed with a safety pressure retaining device, built-in pressure relief valve to prevent overload, to protect the self-locking jack to facilitate safe operation. The connection of the device is connected by high pressure hose and threaded joint, which has the advantages of fast use and overcoming the shortcomings of fast traditional joint oil leakage. It is mainly used for equipment installation and toppling operation in various industries such as electric power, construction, machinery manufacturing, mining, railway bridge, shipbuilding and so on.

The method of sleeve push and pull the cylinder to improve the processing quality: there is a big gap in the service life of post-plating polishing and post-plating polishing, especially in mass production. Strictly clean the flying edge and burr of mechanical components, especially the edge of the sealing groove, and the tiny metal burr, strictly clean before assembly. The surface fatigue strength and stress corrosion resistance of the push and pull the cylinder can be significantly improved by rolling in the finishing of the inner holes of the push and pull the cylinder. The roughness of the surface of the friction pair is generally controlled between Ra0.4 and 0.8.

What type of seal is the cylinder of shaft 50?

You won't know the exact model until you take it apart. Oil seals have O, Y, Yx, KYx, U, UN, UHS, YA, St, Gray, Yamagata, Lei type, etc. It is difficult to know what kind of oil seal the designer chooses. Cylinder oil seal installation method: 1. Receive a fixed number of oil seals. 2. From receiving the oil seal to assembly, it must be kept clean. 3. Before assembly, check the oil seal and measure whether the size of each part of the oil seal is consistent with the size of the shaft and cavity. Before the oil seal is installed, the size of the shaft diameter should be clearly compared with the inner diameter of the oil seal. The inner cavity size should be suitable for the outer diameter width of the oil seal. Check the lip of the oil seal for damage.

Cylinder pressure calculation formula

The pressure of the cylinder at work is determined by the load, and the pressure of the physical force is equal to the force divided by the area of action (that is, P=F/S). If you want to calculate the output force of the cylinder, you can calculate it according to the formula: Set the radius of the piston (that is, the cylinder) is R (unit mm) the radius of the piston rod is r (unit mm) the working pressure P (unit MPa) the thrust of the cylinder F push =3.14*R*R*P (unit N) The pulling force of the cylinder F pull =3.14* (R*R-r* R) *P (unit N).