Release time:2023-11-08 10:37:00 Hits: Current position: Home > News

This article mainly introduces:

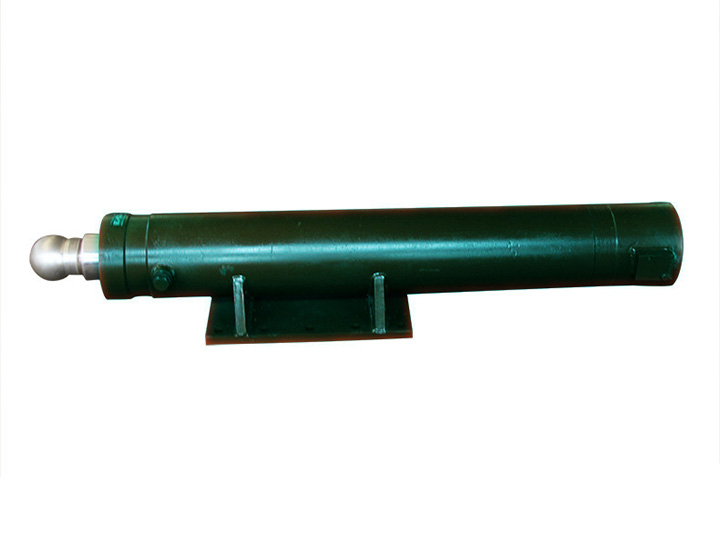

Chile hydraulic cylinder,supporting cylinder manufacturer,supporting cylinder

(Chile supporting cylinder,produced by Hebei Hengyu company)

supporting cylinder are widely used in Chile,because of no transmission clearance,powerful torque,clever hydraulic energy conversion.So our company has designed supporting cylinder for customers from Chile.

The method of sleeve supporting cylinder to improve the processing quality: there is a big gap in the service life of post-plating polishing and post-plating polishing, especially in mass production. Strictly clean the flying edge and burr of mechanical components, especially the edge of the sealing groove, and the tiny metal burr, strictly clean before assembly. The surface fatigue strength and stress corrosion resistance of the supporting cylinder can be significantly improved by rolling in the finishing of the inner holes of the supporting cylinder. The roughness of the surface of the friction pair is generally controlled between Ra0.4 and 0.8.

The difference between the plunger supporting cylinder and the piston supporting cylinder is that the piston in the supporting cylinder is replaced by a shaft plunger, which is used in hydraulic transmission requiring a long mechanical stroke, and can only input pressure oil from one direction, pressurize in a single direction, and form a thrust to push the plunger to move. The return trip of the plunger depends on the plunger itself to fall, and some rely on the spring to push back to the original position. Usually used plunger type supporting cylinder, its inner hole does not need mechanical finishing, as long as the plunger round grinding can be assembled.

In order to ensure the service life of the supporting cylinder, the medium used must not be mixed with impurities and stolen goods, so as to avoid scratching the inner arm of the supporting cylinder, causing damage to the seal and causing leakage in the supporting cylinder. It is required that the filtration accuracy of the system is not less than 80μm, the oil pollution is strictly controlled, the hydraulic oil is kept clean, the performance of the hydraulic oil is regularly checked, and the necessary fine filtration or replacement of the new working hydraulic oil is carried out.

supporting cylinder buffer valve inspection and maintenance: For the valve buffer supporting cylinder, the focus should be on checking the wear of the buffer valve spool and seat. Once it is found that the amount of wear increases and the seal fails, it should be replaced. It can also be repaired by using abrasive spool and seat matching grinding method.

How to control the speed of the cylinder?

High demand control, it is necessary to use servo closed-loop control, you can adjust the speed at will. Reference: Hydrodynamic Motion Control Practical Design Guide.

Cylinder pressure calculation formula

The pressure of the cylinder at work is determined by the load, and the pressure of the physical force is equal to the force divided by the area of action (that is, P=F/S). If you want to calculate the output force of the cylinder, you can calculate it according to the formula: Set the radius of the piston (that is, the cylinder) is R (unit mm) the radius of the piston rod is r (unit mm) the working pressure P (unit MPa) the thrust of the cylinder F push =3.14*R*R*P (unit N) The pulling force of the cylinder F pull =3.14* (R*R-r* R) *P (unit N).