Release time:2023-11-12 11:05:36 Hits: Current position: Home > News

This article mainly introduces:

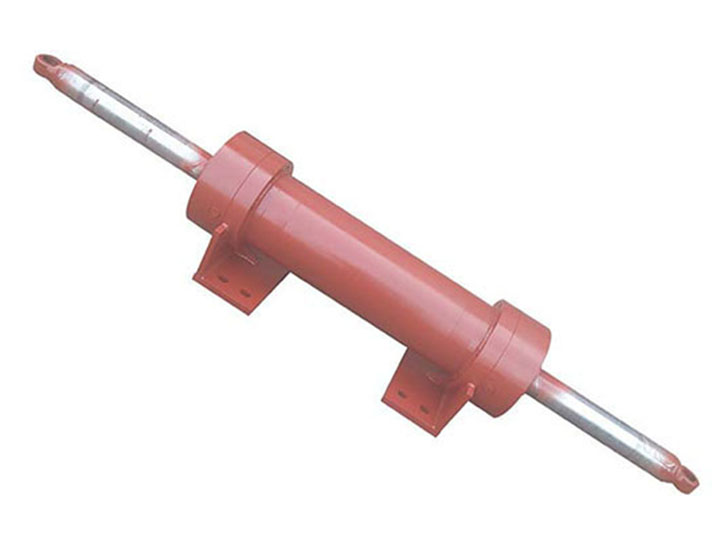

Puerto Rico hydraulic cylinder,vehicle hydraulic cylinder manufacturer,vehicle hydraulic cylinder

(Puerto Rico vehicle hydraulic cylinder,produced by Hengyu Group)

vehicle hydraulic cylinder are widely used in Puerto Rico,because of excellent temperature resistance,no transmission clearance,powerful torque.So our company has designed vehicle hydraulic cylinder for customers from Puerto Rico.

The main role of the vehicle hydraulic cylinder: the vehicle hydraulic cylinder is an executive element in the hydraulic transmission system, which is an energy conversion device that converts hydraulic energy into mechanical energy. The hydraulic motor realizes continuous rotary motion, while the vehicle hydraulic cylinder realizes reciprocating motion. The structure of the vehicle hydraulic cylinder has three categories: piston vehicle hydraulic cylinder, plunger vehicle hydraulic cylinder, swing vehicle hydraulic cylinder, piston vehicle hydraulic cylinder and plunger vehicle hydraulic cylinder to achieve reciprocating linear motion, output speed and thrust, swing vehicle hydraulic cylinder to achieve reciprocating swing, output angular speed (speed) and torque. In addition to the single use of the vehicle hydraulic cylinder, two or more can be combined or used in combination with other mechanisms. To fulfill a special function. The vehicle hydraulic cylinder has simple structure and reliable operation, and has been widely used in the hydraulic system of machine tools.

Classification of vehicle hydraulic cylinder: according to the mode of movement it can be divided into linear reciprocating movement type and rotary swing type; According to the effect of liquid pressure, it can be divided into single acting type and double acting type. According to the structure, it can be divided into piston type, plunger type, multistage telescopic sleeve type, pinion and rack type, etc. According to the installation form can be divided into rod, earring, foot, hinge shaft and so on; According to the pressure grade can be divided into 16Mpa, 25Mpa, 31.5Mpa and so on.

Protection of the vehicle hydraulic cylinder surface: During the dismantling process, safety protection should be carried out on the vehicle hydraulic cylinder to prevent objects from falling and welding slag from falling to the surface, causing damage to the vehicle hydraulic cylinder surface. In the process of propulsion, the damaged pipe segments should be prevented from falling and smashing, and the slurry remaining on the surface of the vehicle hydraulic cylinder should be cleaned up in time.

When the vehicle hydraulic cylinder is in use, ensure that the vehicle hydraulic cylinder and the surrounding environment should be clean. The tank should be sealed to prevent contamination. Pipelines and fuel tanks should be cleaned to prevent falling off the oxide sheet and other debris. Clean with lint-free cloth or special paper. Twine and binder should not be used as sealing materials. Hydraulic oil according to the design requirements, pay attention to the change of oil temperature and oil pressure. When there is no load, unscrew the exhaust bolt for exhaust.

What are the reasons why the hydraulic cylinder action is slower than normal?

There are many factors that cause this problem. First, measure the pressure of the main system to see whether the pressure of the main system under the pressure state is consistent with the initial setting. Before measuring the pressure, it is best to check the hydraulic oil and suction oil filter and replace or clean it. Second, check the main relief valve of the reversing control multiway valve to see if there is damage or foreign matter blocking, and clean it. If your pump is a gear pump, the problem should generally be small. Second, look at traffic. There is no leakage in the cylinder, leakage in the reversing valve spool and so on.

What are the requirements for hydraulic cylinder assembly? ① The installation of the cylinder should be solid and reliable. In order to prevent the influence of thermal expansion, in the case of large stroke and hot working conditions, one end of the cylinder must be kept floating.② pipe connection shall not be relaxed.③ The mounting surface of the hydraulic cylinder and the sliding surface of the piston rod should maintain sufficient parallelism and perpendicality.④ The central axis of the moving cylinder should be concentric with the center line of the load force, otherwise it will cause lateral force, which is easy to wear the seal And piston damage. The greater the distance between the supporting points of the piston rod, the smaller its wear. For the hydraulic cylinder of the moving object, the installation should keep the cylinder parallel with the moving object, and the degree of non-parallelism is generally not greater than 0.05mm/m. ⑤The sealing ring should not be installed too tightly, especially the U-shaped sealing ring.