Release time:2023-11-07 17:47:48 Hits: Current position: Home > News

This article mainly introduces:

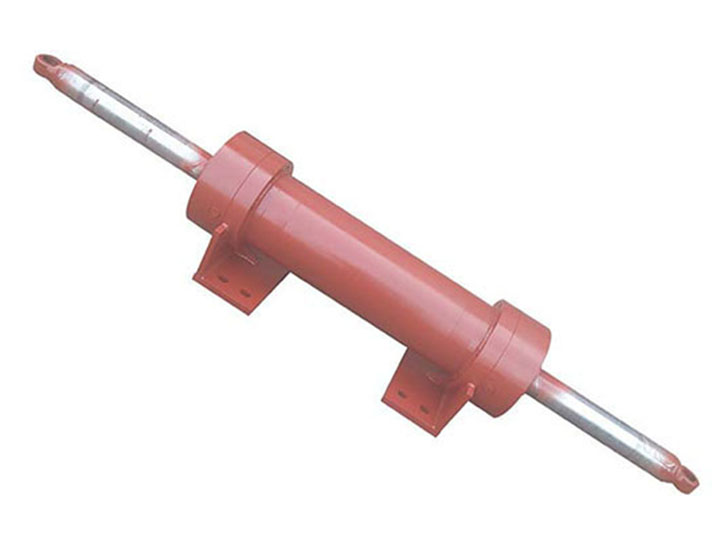

Ireland hydraulic cylinder,vehicle hydraulic cylinder manufacturer,vehicle hydraulic cylinder

(Ireland vehicle hydraulic cylinder,produced by Hebei Hengyu company)

vehicle hydraulic cylinder are widely used in Ireland,because of simple structure and reliable operation,excellent temperature resistance,no transmission clearance.So our company has designed vehicle hydraulic cylinder for customers from Ireland.

The method of sleeve vehicle hydraulic cylinder to improve the processing quality: there is a big gap in the service life of post-plating polishing and post-plating polishing, especially in mass production. Strictly clean the flying edge and burr of mechanical components, especially the edge of the sealing groove, and the tiny metal burr, strictly clean before assembly. The surface fatigue strength and stress corrosion resistance of the vehicle hydraulic cylinder can be significantly improved by rolling in the finishing of the inner holes of the vehicle hydraulic cylinder. The roughness of the surface of the friction pair is generally controlled between Ra0.4 and 0.8.

Factors that should be considered when selecting the oil seal in the vehicle hydraulic cylinder: some specific factors should be taken into account when selecting the oil seal in the vehicle hydraulic cylinder, so as to have correct consideration and get accurate results, and then avoid wrong selection. The factors and aspects that should be taken into account are eight: vehicle hydraulic cylinder diameter, piston rod diameter, piston rod and piston groove size, vehicle hydraulic cylinder working pressure, vehicle hydraulic cylinder movement speed, hydraulic system oil temperature and vehicle hydraulic cylinder working environment.

When the long-stroke vehicle hydraulic cylinder rotates horizontally, the piston rod bends due to its own weight, causing the guide sleeve and piston to produce biased load, resulting in vehicle hydraulic cylinder head seal damage, oil leakage, and piston sleep in the vehicle hydraulic cylinder. The following measures can be taken: increase the piston plan to adjust the piston outer circle and process it into a convex drum, so that the piston can self-position, improve the force situation, and reduce and avoid pulling the vehicle hydraulic cylinder; The piston and the piston rod are connected with a spherical joint.

Classification of vehicle hydraulic cylinder: according to the mode of movement it can be divided into linear reciprocating movement type and rotary swing type; According to the effect of liquid pressure, it can be divided into single acting type and double acting type. According to the structure, it can be divided into piston type, plunger type, multistage telescopic sleeve type, pinion and rack type, etc. According to the installation form can be divided into rod, earring, foot, hinge shaft and so on; According to the pressure grade can be divided into 16Mpa, 25Mpa, 31.5Mpa and so on.

How is the hydraulic cylinder tempered?

The purpose of the tempering treatment is to make the piston rod have comprehensive mechanical properties of strength, hardness, plasticity and toughness, and the internal structure is uniform and fine tempered sorbite, so as to prepare the organization for subsequent surface quenching. The length of the long cylinder piston rod is 3800-4200, and the diameter is Φ90-Φ110mm, so its heating equipment uses a 150KW well resistance furnace or 600KW suspension continuous resistance heating furnace, and the temperature is controlled by two areas. Heat treatment process parameters: in the shaft furnace, a furnace is suspended with 4 pieces, the quenching heating temperature is 830±10℃, and after holding heat for 160min, it is divided into two times for quenching, and two pieces are quenched each time, and the circulating cooling water is used for cooling.

How to limit cylinder push rod rotation?

In general, the push-rod rotation can be limited after the push-rod is connected to the pushed mechanism. For example, the push rod is hinged with the push mechanism, or the push mechanism itself is guided, which can limit the rotation of the push rod.