Release time:2023-11-13 11:19:13 Hits: Current position: Home > News

This article mainly introduces:

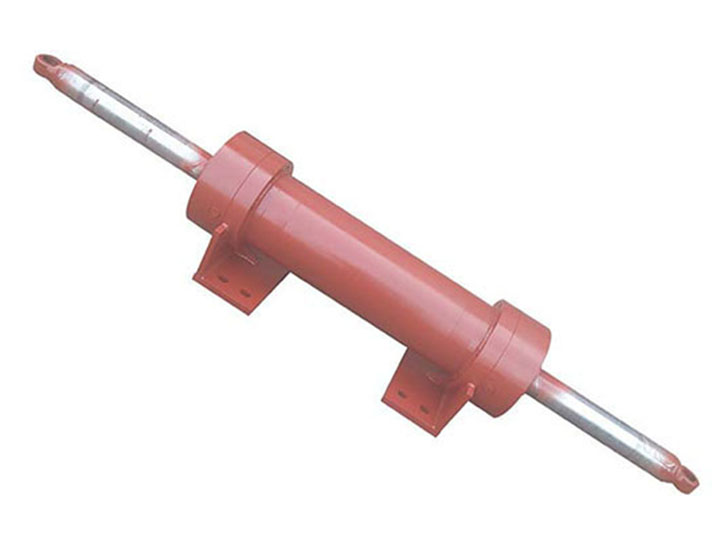

The Philippines hydraulic cylinder,vehicle hydraulic cylinder manufacturer,vehicle hydraulic cylinder

(The Philippines vehicle hydraulic cylinder,produced by Hengyu Hydraulic Co., Ltd)

vehicle hydraulic cylinder are widely used in The Philippines,because of no need for deceleration device,long service life,smooth movement.So our company has designed vehicle hydraulic cylinder for customers from The Philippines.

Causes and countermeasures of oil vehicle hydraulic cylinder leakage: Cast iron ring seal allows a certain degree of internal leakage. The impurities in the vehicle hydraulic cylinder will lead to premature wear of the piston seal, replace the piston seal; If the vehicle hydraulic cylinder is visibly scarred, the vehicle hydraulic cylinder must be replaced. It can be pressurized at one end of the vehicle hydraulic cylinder and opened at the other end of the oil port to observe whether there is obvious internal leakage at the end of the oil port. Most vehicle hydraulic cylinder piston drift may not come from the vehicle hydraulic cylinder, the above method to determine the vehicle hydraulic cylinder without internal leakage is helpful to determine the problem of the hydraulic system related components.

vehicle hydraulic cylinder head explanation: low pressure castings, medium and low pressure with HT300 gray iron, medium and high pressure with 35, 45 steel. When the vehicle hydraulic cylinder head itself is the guide sleeve of the piston rod, the vehicle hydraulic cylinder head is best cast iron. At the same time, brass, bronze or other wear-resistant materials should be fused on the guide surface. If the guide sleeve is pressed into the vehicle hydraulic cylinder head, the guide sleeve shall be wear-resistant cast iron, bronze or brass.

The body of the vehicle hydraulic cylinder on the processing process requirements: the body of the vehicle hydraulic cylinder is an important and essential part of the vehicle hydraulic cylinder, because it has an irreplaceable role. The processing requirements for this part are very high, requiring that the surface roughness of the vehicle hydraulic cylinder after processing should reach 0.4-0.8um, and the coaxiality and wear resistance requirements are also very high.

The vehicle hydraulic cylinder is not the same as the vehicle hydraulic cylinder, because the pressure of the pneumatic system is generally within the range of 0.2-1.0Mpa, the vehicle hydraulic cylinder can not be used as a high-power power component, but the vehicle hydraulic cylinder can be used as a relatively large power component, or the vehicle hydraulic cylinder system can be used.

What is the pressure provided for a 63-bore cylinder with a pressure of 2 mpa?

2 mpa pressure is equivalent to 20 kg per square centimeter, 6.3 cm straight longitude, 3.15 cm radius, square, multiplied by, calculated an area of about 31.5 square centimeters, multiplied by 20 kg, the pressure is about 630 kg.

What is the reason for the hydraulic cylinder sticking out and not retracting?

There are two reasons: First, the problem with the seal, if there are two seals on the piston, the top seal is broken. Second, when the hydraulic pressure itself is designed, the rod cavity area is too small, so that the desired return force can not be achieved during the return trip. You can first check whether the coupling is damaged; Then see if the relief valve in the oil line block is blocked. If the use time is too long, it needs to be cleaned, the hydraulic oil is very dirty and can block oil block. Electromagnetic directional valves can also be checked, but the chance of problems is relatively small, unless there is a product problem.