Release time:2023-11-15 10:41:53 Hits: Current position: Home > News

This article mainly introduces:

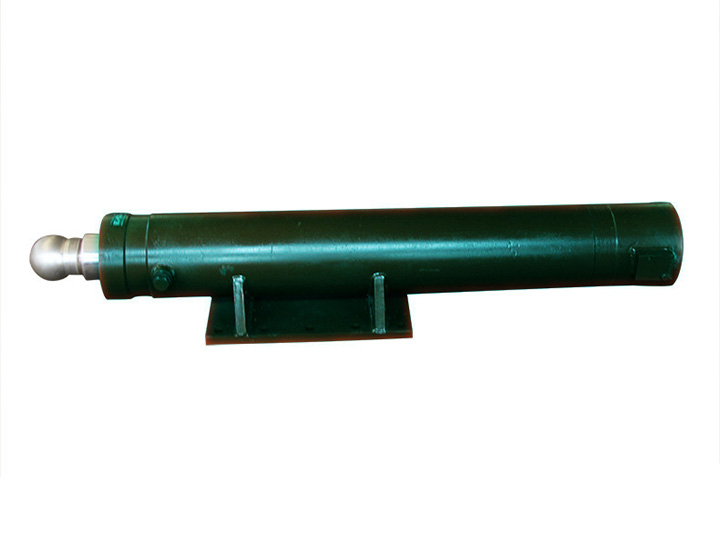

Britain hydraulic cylinder,supporting cylinder manufacturer,supporting cylinder

(Britain supporting cylinder,produced by Hengyu Group)

supporting cylinder are widely used in Britain,because of clever hydraulic energy conversion,simple structure and reliable operation,excellent temperature resistance.So our company has designed supporting cylinder for customers from Britain.

The main role of the supporting cylinder: the supporting cylinder is an executive element in the hydraulic transmission system, which is an energy conversion device that converts hydraulic energy into mechanical energy. The hydraulic motor realizes continuous rotary motion, while the supporting cylinder realizes reciprocating motion. The structure of the supporting cylinder has three categories: piston supporting cylinder, plunger supporting cylinder, swing supporting cylinder, piston supporting cylinder and plunger supporting cylinder to achieve reciprocating linear motion, output speed and thrust, swing supporting cylinder to achieve reciprocating swing, output angular speed (speed) and torque. In addition to the single use of the supporting cylinder, two or more can be combined or used in combination with other mechanisms. To fulfill a special function. The supporting cylinder has simple structure and reliable operation, and has been widely used in the hydraulic system of machine tools.

The supporting cylinder can not be used as grounding electrode to avoid electric damage to the piston rod.

The internal leakage of the supporting cylinder is an important indicator to measure the quality of the supporting cylinder: the internal leakage of the supporting cylinder will reduce the volumetric efficiency, increase the temperature rise of the oil, affect the positioning accuracy of the supporting cylinder, so that the supporting cylinder can not accurately and stably stop in a certain position of the supporting cylinder, so it is one of the main indicators of the supporting cylinder.

If the supporting cylinder is sliding or crawling (stop and go), check whether there is any astringency inside the supporting cylinder. The internal parts of the supporting cylinder are improperly assembled, the parts are deformed, worn or the shape and position tolerance is excessive, and the action resistance is too large, so that the piston speed of the supporting cylinder changes with the different stroke position, and there is slip or crawl. Most of the reasons are due to poor assembly quality of parts, surface scars or sintered iron filings, so that the resistance increases, the speed decreases. For example, the piston is different from the piston rod or the piston rod is bent, the supporting cylinder or the piston rod is offset from the mounting position of the guide rail, and the sealing ring is too tight or too loose. The solution is to repair or adjust, replace damaged parts and remove iron filings. At the same time, check whether the lubrication is good or whether the supporting cylinder bore processing is out of whack. Because the piston and supporting cylinder, guide rail and piston rod are relative If the supporting cylinder is crawling seriously, check whether air has entered the hydraulic system. Air compression or expansion can cause the piston to slip or crawl. The exclusion measures are to check the hydraulic pump, set up a special exhaust device, and quickly operate the exhaust several times in the full stroke. Check the seals at the same time, because the quality of the seals is directly related to slippage or crawling. When the O-ring is used under low pressure, compared with the U-ring, it is easy to slip or crawl because of the higher surface pressure and the larger difference between static and static friction resistance. The surface pressure of the U-shaped sealing ring increases with the increase of pressure, although the sealing effect is correspondingly improved, but the difference between static and static friction resistance is also larger, the internal pressure increases, affecting the rubber elasticity, due to the increase in the contact resistance of the lip, the sealing ring will tip over and the lip elongation, and it is also easy to cause slip or crawling supporting cylinder weight composition and calculation. The weight of the supporting cylinder is composed of the supporting cylinder diameter, the outer diameter and weight of the supporting cylinder, the rod diameter, and the weight of the accessories, so in calculation, it is to add all these together to get the specific value. However, if there are special circumstances, it may be calculated separately. This work can be carried out by yourself, but it can also be carried out by professionals, so that mistakes can be avoided.

What do cylinder internal leakage and external leakage mean?

Internal leakage means that the piston seal in the cylinder is not strict, there is a leak between the two chambers of the cylinder, the oil is still in the cylinder, and the external leakage is that the oil leaks to the outside of the cylinder.

When there is only one hole in the oil inlet and outlet of the hydraulic cylinder, will there be oil leakage?

It is a single acting oil cylinder. This oil cylinder is always driven by hydraulic oil in advance, and is generally pulled back by the spring at the bottom of the piston or the weight of the cylinder piston or the load. But either way, it has nothing to do with any internal leakage. Whether the oil is internally drained is related to the sealing and accuracy of the cylinder itself.