Release time:2023-12-21 12:32:49 Hits: Current position: Home > News

This article mainly introduces:

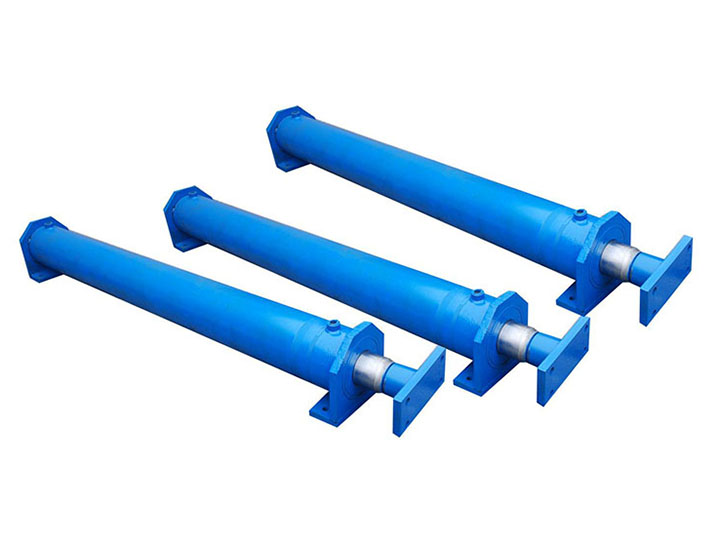

New Zealand hydraulic cylinder,push and pull the cylinder manufacturer,push and pull the cylinder

(New Zealand push and pull the cylinder,produced by Hebei Hengyu company)

push and pull the cylinder are widely used in New Zealand,because of excellent temperature resistance,no transmission clearance,powerful torque.So our company has designed push and pull the cylinder for customers from New Zealand.

The push and pull the cylinder should be used as far as possible to avoid the transverse force, sometimes the piston rod to bear the transverse load is too large, especially do not force or pull the push and pull the cylinder, bite. Elimination method: When installing the push and pull the cylinder, ensure that the axis position of the push and pull the cylinder is consistent with the direction of movement; Make the load borne by the push and pull the cylinder as far as possible through the push and pull the cylinder axis, to avoid the phenomenon of eccentricity.

The piston rod and guide sleeve function of the push and pull the cylinder is crucial: the relative motion pair between the piston rod and the guide sleeve is the main factor causing external leakage, if the chrome layer on the surface of the piston rod is spalling or producing longitudinal tensile marks due to wear, it will directly lead to the failure of the seal.

When the push and pull the cylinder is in use, measures should be added to prevent the intrusion of pollutants. Effective measures should be taken to control the intrusion of pollutants, such as installing high-efficiency air filters in the tank breathing holes, new oil must be filtered, etc., but also must improve the anti-pollution ability of the push and pull the cylinder itself. In the seriously polluted environment, it is more important to pay attention to, such as the underground oil push and pull the cylinder should use fluorine rubber (FRM) and nitrile rubber (NBR) dust ring, and the ground mechanical push and pull the cylinder should use nitrile rubber dust ring; The filter device is added to the oil inlet of the push and pull the cylinder of the dump truck, construction machinery, work platform and other equipment, and in order to reduce the oil inlet resistance, the flow area should be increased as much as possible, which can effectively reduce the particle pollution from the system.

The push and pull the cylinder should be avoided for a long time without use, if it is indeed idle for a long time for some reason, it should also be regularly turned on for empty operation, so that its parts can be fully lubricated, so as to avoid rust on the working surface and affect the normal work in the future. (If it cannot be turned on and run, a small amount of lubricating oil can be applied on its outer surface for protection) ' The use of the push and pull the cylinder should pay attention to: the operation should be as far away from the push and pull the cylinder as possible, to avoid falling objects, knocking, rubbing the push and pull the cylinder coating. When cleaning the push and pull the cylinder, only use soft materials (such as cotton) to wipe, and do not scratch high-hardness materials. Do not use the push and pull the cylinder when the oil temperature exceeds 70 ° C.

What is the cause of the deep scratch of the cylinder?

The following reasons can cause the cylinder to be scratched. 1: Hydraulic oil containing particulate impurities into the hydraulic cylinder, these particulate impurities stuck between the piston rod and the guide ring (or stuck between the piston and the inner wall of the cylinder), when the piston movement in the cylinder will scratch the piston rod, the phenomenon of the inner wall of the cylinder, the more particles, the larger the scratch marks the deeper and more obvious. 2: The body of the cylinder itself. Due to assembly or design reasons, the coaxial error between the piston rod, piston, cylinder, guide ring and other parts is too large, or the cylinder, piston rod straightness error is too large, so that the piston rod and the guide ring interference between the cylinder, this mechanical interference will certainly lose the piston rod or cylinder wall.

The difference between the overall cylinder and the separate cylinder of the truck?

The whole cylinder is cast in one piece, and such a cylinder generally does not leak oil. Split cylinder refers to two welded, easy to leak oil in the welding place, resulting in damage to the cylinder, or its body can not get up, many people do not use this kind of cylinder now.