Release time:2023-11-12 15:33:18 Hits: Current position: Home > News

This article mainly introduces:

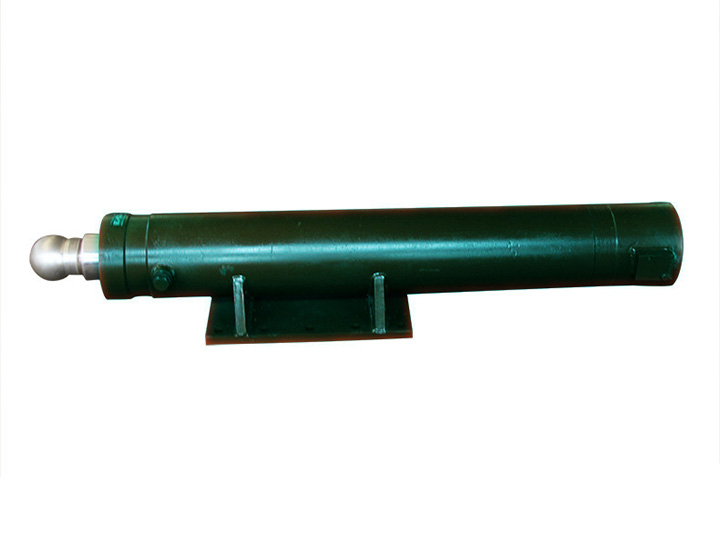

Belarus hydraulic cylinder,supporting cylinder manufacturer,supporting cylinder

(Belarus supporting cylinder,produced by Hebei Hengyu company)

supporting cylinder are widely used in Belarus,because of smooth movement,no need for deceleration device,long service life.So our company has designed supporting cylinder for customers from Belarus.

supporting cylinder daily maintenance, should focus on checking whether the piston rod surface roughness and shape and position tolerance meet the technical requirements, if the piston rod bending should be calibrated to meet the requirements or according to the physical mapping, manufactured by a professional manufacturer. If the piston rod surface coating wear, slip damage, local spalling can be adopted to remove the coating, re-chrome surface processing process.

Piston supporting cylinder is widely used in hydraulic transmission. When the supporting cylinder works, it mainly delivers hydraulic oil alternately to both sides of the piston in the supporting cylinder, and uses the pressure difference of hydraulic oil on both sides of the piston to realize the reciprocating movement of the piston. If you want to speed up the forward speed of the piston, the return oil in the supporting cylinder can be controlled by the valve and directly input into the inlet pipe to participate in the work of the piston to achieve rapid movement of the piston, but the thrust of the piston is reduced much.

Before the supporting cylinder is removed, the system should be unloaded, the loop pressure is zero, the oil source should be cut off, and the oil port should be blocked after the oil port distribution pipe is loosened.

The oil supporting cylinder is a part of the hydraulic system, in the hydraulic system, to reasonably design the heat dissipation system, to prevent the oil temperature is too high is the key to keep the hydraulic oil temperature normal. The temperature of the system should be kept in a suitable range to reduce the energy released when the bubble bursts. While not affecting the normal circulation of the coolant, a certain amount of anti-corrosion additives can be appropriately added to inhibit rust. When operating the hydraulic system, we should strive to be stable, not too fast, too strong, and try to reduce the impact of hydraulic oil on hydraulic components.

How to use a solenoid valve to control the expansion of a cylinder? Doesn't the solenoid valve only control on/off?

Use the solenoid valve P into A-B (generally equipped with oil circuit board) to connect the oil inlet interface at both ends of the cylinder, and the solenoid valve can be realized by power off (refer to the solenoid valve 2B2L, different solenoid valve actions are different).

How to repair if hydraulic shears cylinder oil leakage?

The hydraulic cylinder is generally disassembled and the sealing ring is replaced. There are generally two ways to install the ends of the hydraulic cylinder. The larger hydraulic cylinder is mostly flanged disc type, which is screwed to the middle cylinder block by several bolts, the bolts are removed, and the cylinder head is slowly pulled out. The smaller hydraulic cylinder, the cylinder block and the head itself are threaded, and the rotating end cap can be removed from the cylinder block. If you do not understand the hydraulic cylinder, it is best to ask someone to deal with it. It is easy to damage the sealing ring and internal surface during disassembly.