Release time:2023-11-07 17:47:31 Hits: Current position: Home > News

This article mainly introduces:

Spain hydraulic cylinder,supporting cylinder manufacturer,supporting cylinder

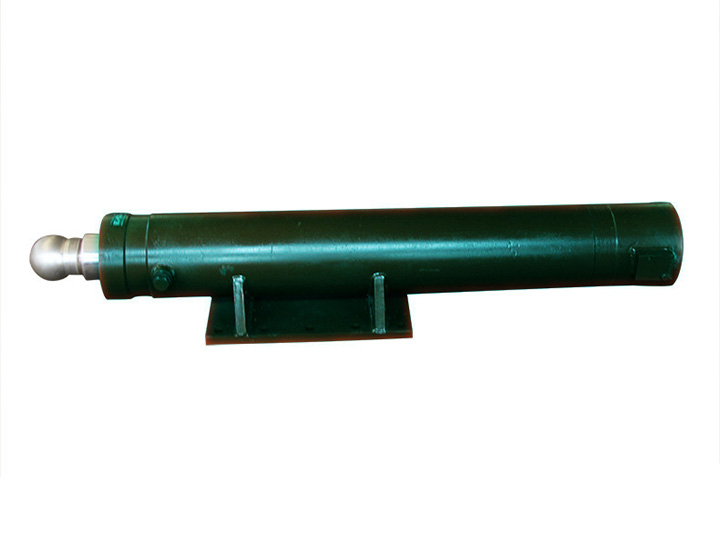

(Spain supporting cylinder,produced by Hengyu Group)

supporting cylinder are widely used in Spain,because of simple structure and reliable operation,excellent temperature resistance,no transmission clearance.So our company has designed supporting cylinder for customers from Spain.

The supporting cylinder is mainly composed of body, piston, piston rod, supporting cylinder head, supporting cylinder bottom, piston rod head and related auxiliary devices. The piston divides the supporting cylinder into two chambers, and moves reciprocally in the supporting cylinder with the help of pressure oil. In order to improve its working effect, there is no sealing ring on the piston to eliminate internal leakage, where the piston rod passes through the supporting cylinder head, due to the existence of the gap, it is easy to produce external leakage phenomenon, and the dust can enter the supporting cylinder through the gap, so the sealing device and dust prevention reason are set. At the same time, in order to eliminate the influence of eccentric load on the work of the piston, all the supporting cylinders must be provided with a considerable length of guide sleeve at the extended end of the piston rod. In addition, in the case of faster piston movement, the phenomenon of mechanical collision between the piston and the supporting cylinder bottom and the supporting cylinder head is serious, so the buffer deceleration should be set at both ends of the supporting cylinder The working medium of the supporting cylinder: because it works at room temperature, the ordinary oil-type hydraulic oil can be selected; supporting cylinder sealing device: The use of Yx sealing ring, polyurethane (PU) and polytetrafluoroethylene (PTFE) materials combined to achieve a good sealing effect; Buffer mechanism of the supporting cylinder: The buffer structure of the supporting cylinder is to prevent the piston from colliding with the supporting cylinder head at the end of the stroke.

When the supporting cylinder is installed, it is necessary to ensure that the direction of the connecting head at the top of the piston rod should be consistent with the direction of the supporting cylinder head, earring (or middle hinge shaft), and ensure the straightness of the whole piston rod during the advance and return process to prevent rigid interference and cause unnecessary damage.

In use, the supporting cylinder should try to avoid the friction iron powder or iron filings formed by buffering the plunger. When the matching gap of the buffer device is small and the transverse load on the piston rod is large, the sintering phenomenon may be caused. These friction iron powder or the metal fragments that have fallen off as a result of sintering will remain in the supporting cylinder.

The supporting cylinder pipe should not be left behind when deburring at both ends after the fixed length processing. In addition, the placement of steel pipes near the site of welding pipeline operations is the cause of welding foreign objects. The pipes placed near the welding operation site should be sealed. It must also be noted that pipe fitting materials should be fully prepared on a dust-free workbench.

What is the difference between hollow and solid oil cylinders?

Hollow solid cylinder, according to conventional understanding, refers to whether the piston rod is solid or hollow. General ordinary hydraulic cylinder, the piston rod is solid structure. Hollow hydraulic cylinder refers to a hollow piston rod structure of the hydraulic cylinder, see the attached figure. Piston rod hollow function: 1, the piston rod hollow, the middle can be threaded rod. For example, the clamping cylinder with a sawing machine, the piston rod center threading rod, part of the stroke through manual, part of the stroke hydraulic automatic walk. 2, the hollow hole of the piston rod can be used to direct the oil circuit to achieve special oil circuit. 3, the cylinder is relatively large, the piston rod is relatively large, and the stroke is longer, in this case, the piston rod is hollow to reduce the movement friction and lateral force.

What are the main dimensions of the cylinder?

The main dimensions of the cylinder include: cylinder inner diameter, piston cylinder diameter, cylinder length, cylinder wall thickness, stroke, installation distance, etc.