Release time:2023-12-09 16:24:36 Hits: Current position: Home > News

This article mainly introduces:

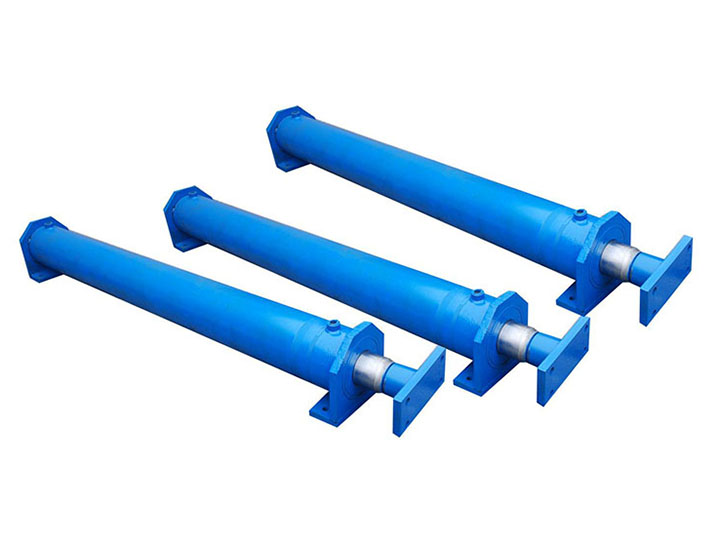

Sri Lanka hydraulic cylinder,push and pull the cylinder manufacturer,push and pull the cylinder

(Sri Lanka push and pull the cylinder,produced by Hebei Hengyu company)

push and pull the cylinder are widely used in Sri Lanka,because of excellent temperature resistance,no transmission clearance,powerful torque.So our company has designed push and pull the cylinder for customers from Sri Lanka.

The internal leakage of the push and pull the cylinder should be prevented when the push and pull the cylinder is used. The internal leakage of push and pull the cylinder includes the leakage caused by excessive wear of push and pull the cylinder block seal, piston rod and seal cover seal and piston seal. The cause of sealing leakage between the piston rod and the seal cover is that the seal is wrinkled, squeezed, torn, worn, aging, deterioration, deformation, etc., and a new seal should be replaced at this time.

When the long-stroke push and pull the cylinder rotates horizontally, the piston rod bends due to its own weight, causing the guide sleeve and piston to produce biased load, resulting in push and pull the cylinder head seal damage, oil leakage, and piston sleep in the push and pull the cylinder. The following measures can be taken: increase the piston plan to adjust the piston outer circle and process it into a convex drum, so that the piston can self-position, improve the force situation, and reduce and avoid pulling the push and pull the cylinder; The piston and the piston rod are connected with a spherical joint.

The advantages and disadvantages of the push and pull the cylinder: the surface of the push and pull the cylinder by painting, coating protection treatment, bright luster is not easy to rust, all raw materials of the push and pull the cylinder through the top heat treatment, high manufacturing precision, belongs to the precision machinery, has a simple structure, stable quality, high mechanical efficiency, easy to achieve automation and many other advantages. However, hydraulic technology also has the shortcomings of oil leakage, oil temperature change affecting the control of running speed, noise, expensive cost and high maintenance cost.

When the piston speed of the push and pull the cylinder is high, the steel ball of the check valve flows with the oil flow, so that the valve hole is blocked, and the push and pull the cylinder moves irregularly. Elimination method: Replace the steel ball with a cone valve or spool with a guide shoulder.

How to choose cylinder size, pump type, motor power for a 30-ton press?

30 tons = 30,000 kg. It is expected to use a 16 mpa oil pump, then the cylinder area =30000/(160x3.14) and then square, the cylinder bore is 150 mm. Calculated at 500 mm travel per minute, the flow rate per minute is :0.75^2x3.14x5=8.8 liters/minute. Motor power =8.8x16/60=2.355. A 9 L/min, 16 mpa pump is available. Piston diameter 150 mm cylinder. 3 kW motor.

How to distinguish cylinder rod head and cylinder bottom?

One end of the piston rod can be telescopic is the rod head, and the one behind is the bottom of the cylinder, which is the single rod cylinder.